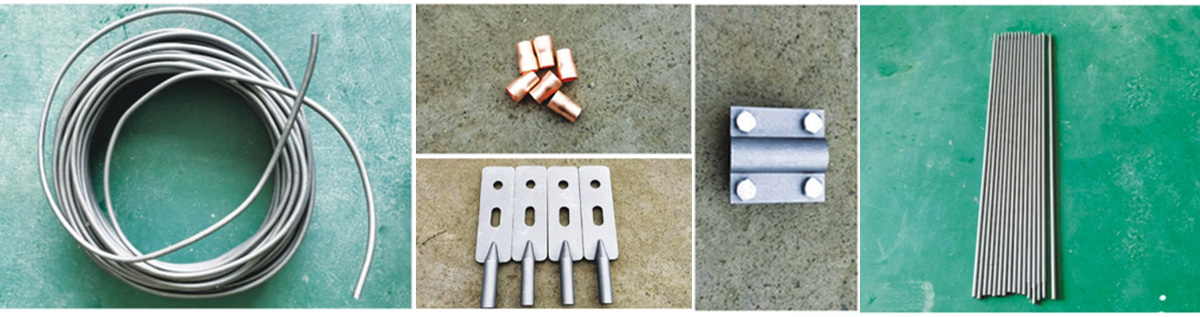

Graphene Grounding Electrode Description:

The core of graphene alloy grounding device adopts φ195 round steel is made into a 1.2M long rod core using a CNC machine, and various metal materials such as graphene, silver powder, aluminum powder, zinc powder, and copper powder are used. Made through the process of infiltration hot plating, the combination of various metal materials and steel is a combination of metal molecules, without electrochemical corrosion of the primary battery effect, with good conductivity, fast discharge speed, lightning resistance, and no need for any anti-corrosion treatment. lts anti-corrosion mechanical life can reach 40 years.

Graphene Grounding Electrode Advantages:

1. Anti Corrosion Performance:

According to the standard clause GB/T21698-2008, the inspection method for the corrosion rate test of 69 grounding electrodes after grounding. The measured corrosion rate is 0.0003mm/year, far below the inspection requirement of 0.03mm/year. According to the national standard GB6458-86 Salt Spray Test, the product did not show significant corrosion after 500 hours of face testing, meeting the testing requirements. The service life of other products on the market is far lower than that of graphite thin grounding products

2. Conductivity

According to the DL/T1312-2013 testing standard, tests were conducted on resistivity, relative conductivity, and short-term withstand current. The measured DC resistivity was 403pcm, relative conductivity was42.8%, and short-term withstand current was 1724KA/s.

Graphene Grounding Electrode Technical Requirements:

a. Specifications and dimensions φ16mm single length is 1.2m

b. The thickness of the graphene alloy layer adopts the graphene alloy (infiltration hot plating) process, and the thickness of the graphene metal layer is≥0.25mm, with an error of no more than 0.001mm

C. Tensile strength: ≥680N/mm2

d. Straightness error: ≤1mm/m

e. Plasticity of graphene metal layer: When the grounding rod is bent at 30 degrees, there are no cracks inside or outside the bending angle

f. Graphene metal layer bonding (requirement for adhesion of graphene metal layer): capable of being cut by a lathe from the surface of the grounding rod to the inside, making it less than the original diameter of 1m ŋ Turning to expose the graphene metal layer and steel rod, with no peeling of the graphene metal layer

g. Manufacturing process: graphene alloy (infiltration hot plating) process

h. Purity of graphene metal in the graphene metal layer:≥99%

i. DC resistivity≥11.15 μ 0cm, conductivity: ≥155%

J. Its annual corrosion rate is below 8.0 µ m. The unused parts with a service life of ≥40 years shall not be lower than the current standard specifications, and when there are no relevant specifications, they shall not be lower than the industry requirements, and shall obtain a national recognition certificate for relevant parts