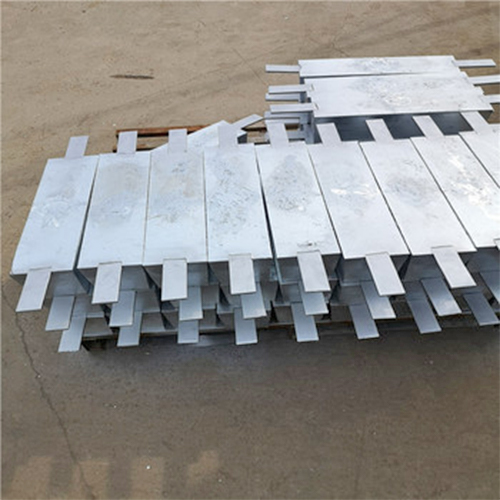

Zinc Alloy Sacrificial Anode Characteristics:

Zinc alloy sacrificial anode is based on electrochemical principles, it uses the more active electrochemical properties of zinc to prevent the corrosion of other metals. When the zinc alloy sacrificial anode is in contact with the metal to be protected, it will voluntarily oxidize and transfer the corrosion reaction of the metal to itself. This reaction can effectively slow down or prevent the corrosion of metal structures, and extend their service life.

Zinc Alloy Sacrificial Anode Features:

1) Excellent anti-corrosion ability: zinc alloy sacrificial anode can provide reliable anti-corrosion protection and effectively resist corrosion in the atmosphere, soil and water.

2) Automatic adjustment function: zinc alloy sacrificial anode can automatically adjust the current output according to the change of corrosive environment to ensure that it is always in good working condition.

3) Long life: zinc alloy sacrificial anode has a long life, usually lasts for several years or more.

4) Easy installation and maintenance: zinc alloy sacrificial anode is relatively simple to install and maintain, just make sure it is in good contact with the metal to be protected.

Zinc Alloy Sacrificial Anode Application:

Zinc alloy cathodic protection is a kind of metal material commonly used for anti-corrosion and corrosion prevention. It is widely used in marine engineering, oil field equipment, ships and bridges, and plays a role in protecting infrastructure effectively.

1. Marine engineering: there are serious corrosion and oxidization conditions in the marine environment, zinc alloy sacrificial anode can provide effective protection to protect offshore platforms, oil rigs and other equipment.

2. Ship: Zinc alloy sacrificial anode is used for anti-corrosion protection of ship hull, propellers and other ship parts to reduce the damage of ship structure.

3. Bridges: Bridges are often exposed to the atmosphere and are prone to corrosion, zinc alloy sacrificial anode can extend the service life of bridges and reduce the maintenance cost.

4. Pipelines and storage tanks: Zinc alloy sacrificial anode is widely used for anti-corrosion protection of oil and gas pipelines and storage tanks to ensure their safe operation.

Zinc Alloy Sacrificial Anode Construction:

1)Sacrificial anode should be connected with pipeline through test pile for future management. Sacrificial anode and pipeline direct connection, will give the future sacrificial anode performance measurement, pipeline potential measurement, leakage detection of corrosion protection layer and stray current control will bring difficulties.

2) Sacrificial anodes are distributed along the protected structure, generally installed horizontally or vertically, and buried below the frozen soil layer. For cathodic protection of pipeline, the anode is generally flush with the bottom of the pipeline.

3) When the corrosion protection layer of the pipeline is good, there is little difference between horizontal and vertical installation and whether it is installed near the pipeline or not. Several anodes can be installed in groups and connected to the pipeline through test piles.

4) When installing sacrificial anodes under water environment, their distribution should be as even as possible, and they should be welded or riveted on the protected structure.

5) When installing the pre-packed sacrificial anode, the anode should be basically in the central position of the packing material, and pay attention to the dislocation caused by transportation. The pre-packed sacrificial anode shall be immersed in water for more than 50min after entering the pit.

6) When installing zinc or magnesium belt, the anode should be backfilled with packing material, and the thickness of packing material is generally more than 5cm (12kg/m).